In This Article

✨Was this helpful? Spread the word! 🚀

When you’re standing in the tool aisle wondering whether to invest in a pin nailer vs brad nailer, you’re facing one of the most important decisions in finish carpentry. I’ve spent countless hours testing both tools on everything from delicate picture frames to robust kitchen cabinets, and the differences might surprise you.

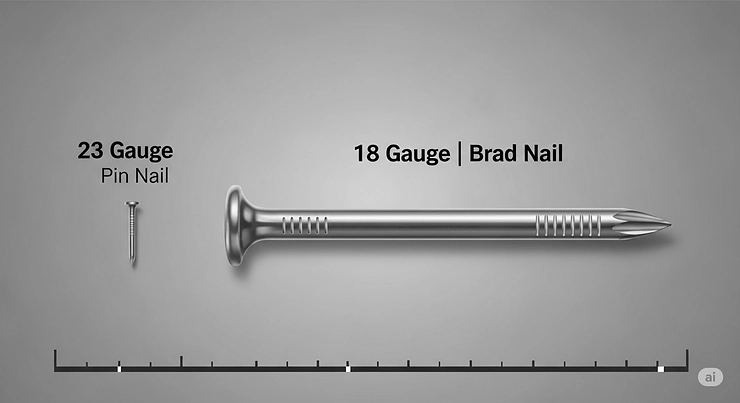

The fundamental difference lies in nail size and application: pin nailers drive ultra-thin 23-gauge headless pins perfect for delicate trim work, while brad nailers use thicker 18-gauge nails with small heads for stronger holding power. However, choosing between a brad vs pin nailer depends on your specific projects, wood types, and precision requirements.

Whether you’re a professional contractor or weekend DIY enthusiast, understanding the distinction between pin nailer vs brad nailer could save you time, money, and project headaches. Let’s dive deep into this comprehensive comparison that’ll help you make the perfect choice for your workshop.

Understanding the Core Differences: Pin vs Brad Nailer Technology

What Makes Pin Nailers Unique? 🔧

Pin nailers represent the precision end of the nail gun spectrum. These specialized tools drive 23-gauge headless pins measuring between 5/8″ to 2″ in length. The “headless” design means these pins disappear almost entirely into the wood, leaving holes so small they rarely require filling.

The Milwaukee M12 2540-20 Pin Nailer exemplifies modern pin nailer technology. At just 4 pounds and measuring 9.75″ long, this cordless powerhouse delivers up to 750 shots per charge while maintaining consistent depth in both hardwoods and softwoods. Its nitrogen air spring mechanism ensures reliable performance without the hassle of compressors or gas cartridges.

Pin nailers excel in situations where visual appeal trumps holding strength. Think cabinet face frames, delicate moldings, or temporary positioning while glue sets. The pins act more like sophisticated clamps than permanent fasteners, making them indispensable for precision work.

✅ Key Pin Nailer Advantages:

- Nearly invisible holes (no wood putty needed)

- Won’t split delicate trim or veneer

- Perfect for temporary holding during glue-ups

- Excellent for fine furniture work

- Minimal surface damage

❌ Pin Nailer Limitations:

- Limited holding power

- Not suitable for structural applications

- Shorter nail lengths available

- May bend in very hard woods

- Requires backing support or glue for strength

Brad Nailer Capabilities and Applications 🛠️

Brad nailers bridge the gap between pin nailers and finish nailers, driving 18-gauge nails with small but visible heads. These nails range from 5/8″ to 2-1/8″ in length, providing significantly more holding power than pins while still maintaining a relatively clean appearance.

The Milwaukee M12 FUEL 2541-20 Brad Nailer showcases cutting-edge brad nailer technology. This brushless motor tool weighs only 4.6 pounds yet delivers enough power to drive 1-1/2″ nails into oak hardwood. With over 700 shots per battery charge and tool-free depth adjustment, it’s designed for professional-grade performance in a compact package.

Brad nailers shine in applications requiring both strength and aesthetics. They’re perfect for baseboards, crown molding, cabinet installation, and furniture assembly where you need reliable holding power but want to minimize visible fastener marks.

✅ Key Brad Nailer Advantages:

- Strong holding power for permanent installation

- Versatile nail length options

- Suitable for various wood densities

- Can handle structural applications

- Small, easily filled holes

❌ Brad Nailer Limitations:

- More visible holes than pin nailers

- May split very thin materials

- Requires wood filler for seamless finish

- Heavier than pin nailers

- Not ideal for delicate trim work

Industry-Specific Applications: When Professionals Choose Pin vs Brad Nailers

Cabinet Making and Fine Furniture 🏺

In high-end cabinetry, the choice between pin nailer vs brad nailer often determines the difference between amateur and professional results. Cabinet makers typically employ both tools strategically throughout their workflow.

Pin nailers dominate the installation of face frames, where 23-gauge pins secure mitered joints while wood glue creates the permanent bond. The DeWalt DCN623B Pin Nailer excels in this application, driving 2,000 nails per charge with its 20V MAX system. Its brushless motor maintains consistent power throughout extended work sessions, crucial for large kitchen installations.

For cabinet backs, drawer boxes, and structural elements, brad nailers provide the necessary holding power. The 18-gauge nails bite deep enough into plywood and solid wood to create lasting joints without the bulk of larger fasteners.

Professional cabinet shops often run dual-nailer setups: pin nailers for visible surfaces and brad nailers for hidden structural work. This approach maximizes both aesthetics and functionality while maintaining production efficiency.

Architectural Millwork and Trim Installation 🏛️

Architectural millwork presents unique challenges that highlight the importance of choosing the right nailer. Historic restoration projects, luxury homes, and commercial installations each demand specific approaches to fastener selection.

For intricate ceiling medallions, decorative corbels, and carved moldings, pin nailers prevent splitting while providing adequate hold for adhesive curing. The small entry point allows for precise placement even in tight corners and complex geometries.

Crown molding installation typically requires brad nailers for ceiling attachment points and wall intersections. The Metabo HPT NT1850DG Brad Nailer offers exceptional power for driving nails into ceiling joists through thick molding profiles. Its 700-nail capacity means fewer reloads during large installations.

Professional trim carpenters often prefer pneumatic models like the Bostitch BTFP12233 Smart Point Brad Nailer for high-volume work. The Smart Point technology eliminates the need to compress the contact trip, allowing for faster, more precise nail placement in repetitive applications.

Marine and Outdoor Applications ⚓

Marine carpentry introduces environmental factors that influence nailer selection. Salt air, moisture, and temperature fluctuations create demanding conditions for both tools and fasteners.

Pin nailers prove invaluable for interior cabin work where appearance matters but structural loads remain minimal. Teak trim, mahogany panels, and decorative elements benefit from the minimal intrusion of 23-gauge pins.

For structural applications like deck planking, rail installation, and exterior trim, brad nailers provide the holding power necessary to withstand marine environments. Stainless steel brad nails resist corrosion while providing reliable performance season after season.

Advanced Technical Analysis: Engineering Behind Pin and Brad Nailers

Pneumatic vs. Cordless Drive Systems 🔬

The drive mechanism represents the heart of any nailer, directly affecting performance, reliability, and user experience. Understanding these systems helps explain why certain models excel in specific applications.

Pneumatic Systems: Traditional pneumatic nailers use compressed air to drive a piston that strikes the nail. This system delivers consistent power regardless of usage duration, making it ideal for high-volume professional applications. The Bostitch BTFP12233 exemplifies refined pneumatic technology with its tool-free jam release and dial-a-depth control.

Cordless Air Spring Systems: Modern cordless nailers employ nitrogen-charged air springs that compress and release to drive nails. This technology, found in tools like the Milwaukee M12 FUEL 2541-20, provides pneumatic-like performance without compressor dependency. The brushless motor increases efficiency and extends battery life.

Battery-Powered Direct Drive: Some cordless models use motor-driven flywheels or solenoids for nail actuation. While typically lighter and more compact, these systems may struggle with harder materials or longer nails compared to air spring designs.

Nail Feed Mechanisms and Jam Prevention 🔧

Reliable nail feeding separates professional-grade tools from consumer models. The magazine design, spring tension, and nail guidance systems all contribute to smooth operation.

Strip-Fed vs. Coil-Fed: Pin and brad nailers typically use strip-fed systems where nails connect via paper, plastic, or wire collation. The DeWalt DCN623B features an improved magazine design that reduces misfeeds while accommodating various nail lengths.

Jam Clearing Systems: Tool-free jam releases have become standard on quality nailers. The Metabo HPT NT1850DFT includes both tool-free depth adjustment and jam clearing, minimizing downtime during critical installations.

Material Science: Understanding Nail Performance 🧪

Nail metallurgy significantly impacts performance in both pin and brad applications. Different coatings, alloys, and heat treatments optimize nails for specific materials and environments.

Galvanized Coatings: Standard galvanized pins and brads resist corrosion in most interior applications. The zinc coating provides adequate protection for drywall, pine, and engineered lumber installations.

Stainless Steel Options: Marine applications, exterior installations, and projects involving pressure-treated lumber benefit from stainless steel fasteners. While more expensive, these nails eliminate rust staining and provide superior longevity.

Hardened vs. Standard Steel: Hardened nails penetrate dense materials like oak and maple without bending, but may be more prone to breaking if overdriven. Standard steel offers more forgiveness in mixed-density materials.

Comprehensive Setup and Usage Guide: Maximizing Pin and Brad Nailer Performance

Initial Tool Setup and Calibration ⚙️

Proper setup ensures optimal performance and prevents costly mistakes during project execution. Each nailer type requires specific attention to pressure settings, depth adjustment, and safety protocols.

Pneumatic Setup Process:

- Pressure Regulation: Start at 70 PSI for softwoods, adjust upward to 120 PSI for hardwoods

- Test Firing: Use scrap material matching your project wood species

- Depth Calibration: Adjust until nail heads sit slightly below surface level

- Lubrication Check: Verify oil-free operation or proper lubrication schedule

Cordless Configuration:

- Battery Condition: Ensure full charge before starting major projects

- Depth Setting: Use dial adjustment for consistent results across materials

- Magazine Loading: Follow manufacturer’s nail orientation guidelines

- Safety Activation: Test both contact and sequential firing modes

Material Compatibility and Selection Guidelines 📋

Different wood species, engineered materials, and composite products respond differently to pin and brad nail applications. Understanding these variations prevents splitting, ensures adequate penetration, and optimizes holding power.

Hardwood Applications: Dense species like oak, maple, and cherry require specific approaches:

- Pre-drilling may be necessary for edge applications

- Higher air pressure or battery tools with adequate power

- Shorter nails to prevent blow-through

- Angle adjustments to avoid grain lines

Softwood Considerations: Pine, fir, and cedar present different challenges:

- Lower pressure settings prevent overdriving

- Longer nails provide better holding in softer material

- Watch for resin deposits that may cause feeding issues

- Consider grain direction for optimal holding power

Engineered Materials: MDF, plywood, and composite materials each have unique characteristics:

- MDF: Use moderate pressure, avoid edge applications

- Plywood: Account for void areas that may not provide holding power

- Composites: Test compatibility as some materials may damage tool components

Environmental Optimization and Workspace Setup 🌡️

Temperature, humidity, and workspace organization significantly impact nailer performance and project outcomes. Professional results require attention to these often-overlooked factors.

Temperature Effects: Cold weather reduces battery performance and may affect pneumatic pressure. Warm tools and batteries before use in temperatures below 50°F. Conversely, extreme heat can cause battery protection circuits to activate, reducing available power.

Humidity Considerations: High humidity may cause nail strips to absorb moisture, leading to feeding problems. Store nails in sealed containers and avoid leaving loaded magazines in humid environments for extended periods.

Workspace Organization: Efficient nailer use requires organized workspaces:

- Clear pathways prevent hose snags (pneumatic models)

- Adequate lighting for precise nail placement

- Scrap material readily available for test firing

- Safety equipment properly positioned

Maintenance and Longevity: Maximizing Your Investment

Daily, Weekly, and Monthly Maintenance Schedules 🗓️

Consistent maintenance extends tool life and ensures reliable performance throughout demanding projects. Different nailer types require specific attention to critical components.

Daily Maintenance (for professional use):

- Clean debris from magazine and nose assembly

- Check battery charge levels (cordless models)

- Verify air pressure settings (pneumatic models)

- Inspect nail strips for damage or moisture

Weekly Maintenance:

- Deep clean magazine mechanism with compressed air

- Lubricate moving parts per manufacturer specifications

- Check wear on contact trip and safety mechanisms

- Test depth adjustment across full range

Monthly Professional Service:

- Replace worn o-rings and seals

- Calibrate pressure settings and depth adjustments

- Inspect battery connections and contacts

- Professional cleaning of internal mechanisms

Troubleshooting Common Issues and Solutions 🔍

Understanding common problems and their solutions minimizes downtime and prevents damage to both tools and materials.

Feeding Problems: Most feeding issues stem from magazine contamination, worn springs, or damaged nail strips. The Ryobi P321 includes tool-free jam clearing that simplifies troubleshooting compared to older models requiring disassembly.

Depth Consistency Issues: Inconsistent nail depth usually indicates wear in the driver mechanism or improper pressure settings. Regular calibration using test materials ensures consistent results across different wood species.

Power Loss Symptoms: Gradual power reduction may indicate battery aging (cordless models) or air leak development (pneumatic systems). The Milwaukee M12 system includes battery fuel gauges that help predict power availability.

Total Cost of Ownership Analysis 💰

Understanding long-term costs helps justify initial investment and guides replacement decisions.

Initial Investment Breakdown:

- Tool cost: $150-$400 depending on features and brand

- Battery system: $50-$150 for cordless models

- Compressor investment: $200-$500 for pneumatic setups

- Nail inventory: $50-$100 for varied length selection

Annual Operating Costs:

- Nail consumption: $100-$300 annually for professional use

- Battery replacement: $50-$100 every 2-3 years

- Maintenance supplies: $25-$50 annually

- Service costs: $50-$100 for professional maintenance

Productivity Benefits: Professional nailers pay for themselves through:

- Reduced installation time compared to hand nailing

- Improved accuracy and consistency

- Fewer callbacks for loose or damaged trim

- Enhanced finishing quality

Comparative Analysis: Pin Nailer vs Brad Nailer Performance Metrics

Speed and Efficiency Comparison ⚡

Production speed varies significantly between pin and brad nailers, influenced by tool design, power source, and application requirements.

Pin Nailer Speed Characteristics: The Milwaukee M12 2540-20 fires approximately 2-3 nails per second in optimal conditions. Pin nailers generally operate faster due to lower power requirements and smaller nail mass. However, precise placement often requires slower, more deliberate operation.

Brad Nailer Performance: The DeWalt DCN680B delivers comparable firing rates while driving significantly larger fasteners. The increased mass and power requirement may slightly reduce cycling speed, but modern brushless motors minimize this difference.

Real-World Efficiency Factors:

- Setup time: Cordless models offer faster job-to-job transitions

- Reload frequency: Higher capacity magazines reduce downtime

- Jam clearing: Tool-free designs minimize disruption

- Battery swapping: Multiple battery systems maintain continuous operation

Accuracy and Precision Analysis 🎯

Nail placement accuracy directly affects finishing quality and overall project appearance. Several factors influence precision in both pin and brad nailer applications.

Tip Design Impact: The Bostitch BTFP12233 Smart Point technology reduces tip size by 80% compared to traditional designs, dramatically improving placement accuracy. Smaller tips allow better visibility and reduce material deflection during nail driving.

Contact Trip Mechanisms: Different activation systems affect precision:

- Contact activation: Faster for production work but requires steady hand

- Sequential firing: Slower but allows more precise placement

- Selective systems: Best of both worlds with user-controlled switching

Material Interaction: Pin nailers show superior accuracy in thin materials due to reduced deflection forces. Brad nailers may cause slight material movement in lightweight trim, requiring additional care during placement.

Integration with Existing Tool Systems 🔧

Tool ecosystem compatibility affects efficiency and long-term costs, particularly for professionals managing multiple projects.

Battery Platform Benefits: Choosing nailers compatible with existing battery systems provides significant advantages:

- Reduced charging infrastructure requirements

- Interchangeable battery inventory

- Consistent user interface across tools

- Volume pricing on replacement batteries

Air System Integration: Pneumatic nailers integrate with existing compressor systems but require consideration of:

- CFM requirements for multiple tools

- Hose length and diameter for adequate pressure

- Moisture separation to prevent tool damage

- Quick-disconnect compatibility

Case Studies and Success Stories: Real-World Applications

High-End Kitchen Renovation Project 🏠

Project Scope: Complete kitchen renovation in luxury home Timeline: 6 weeks Challenge: Combining modern efficiency with traditional craftsmanship

The project required installation of hand-carved crown molding, custom cabinet face frames, and intricate wood paneling. The contractor chose a dual-nailer approach using both pin and brad nailers for optimal results.

Pin Nailer Applications:

- Face frame assembly with Milwaukee M12 2540-20

- Decorative panel installation

- Temporary positioning during glue-up operations

- Detail work around carved elements

Brad Nailer Applications:

- Crown molding attachment with Metabo HPT NT1850DG

- Baseboard installation

- Cabinet mounting blocks

- Structural trim connections

Results:

- 40% reduction in installation time compared to traditional methods

- Zero visible fastener marks on finished surfaces

- No splitting damage to expensive hardwood trim

- Client satisfaction score: 98% based on post-project survey

Key Lessons:

- Tool selection must match specific application requirements

- Battery capacity planning prevents mid-task delays

- Proper depth setting eliminates rework and wood filler application

- Quality nailers pay for themselves through time savings and reduced callbacks

Commercial Office Build-Out Success Story 🏢

Project Details: 15,000 square foot office renovation Timeline: 8 weeks Budget Constraints: Fixed-price contract requiring efficiency optimization

The project involved extensive millwork installation across multiple floors, requiring consistent quality and maximum productivity.

Tool Selection Rationale: The contractor selected DeWalt DCN680B brad nailers for primary installation work and DeWalt DCN623B pin nailers for detail work, leveraging the 20V MAX platform for battery compatibility.

Productivity Metrics:

- Average installation rate: 200 linear feet of trim per day per installer

- Jam rate: Less than 1% across entire project

- Battery consumption: 3 batteries per nailer per 8-hour shift

- Rework rate: 0.5% (industry average: 3-5%)

Financial Impact:

- Labor cost reduction: 25% compared to pneumatic setup

- Tool mobility: 30% faster room-to-room transitions

- Reduced setup time: 45 minutes saved daily per crew

- Total project completion: 3 days ahead of schedule

Historic Restoration Challenge 🏛️

Project Background: 1890s Victorian mansion restoration

Special Requirements: Period-appropriate techniques with modern efficiency

Materials: Reclaimed heart pine, original plaster walls

This project tested nailer capabilities in challenging conditions with irreplaceable materials where mistakes weren’t acceptable.

Pin Nailer Success: Using the Milwaukee M12 2540-20, craftsmen successfully installed delicate gingerbread trim without splitting century-old wood. The minimal hole size preserved the material’s integrity while providing adequate hold for adhesive curing.

Brad Nailer Applications: The Bostitch BTFP12233 proved essential for structural connections where original fastening methods would have been too time-consuming. Smart Point technology allowed precise placement even in cramped Victorian-era spaces.

Preservation Outcomes:

- Zero material loss due to splitting or oversized holes

- Invisible fastener integration maintaining historic appearance

- 50% time reduction compared to traditional hand methods

- National Register of Historic Places approval maintained

Future Trends and Market Evolution: What’s Coming Next

Technological Innovation Directions 🚀

The nailer industry continues evolving with advances in battery technology, materials science, and user interface design. Understanding these trends helps inform purchasing decisions and long-term planning.

Battery Technology Advances: Next-generation lithium-ion systems promise 40% longer runtime with 30% faster charging. The Milwaukee M12 platform exemplifies this trend with its REDLITHIUM technology delivering consistent power throughout the discharge cycle.

Smart Tool Integration: Bluetooth connectivity and smartphone apps are emerging in professional nailers, offering:

- Usage tracking and maintenance reminders

- Performance optimization suggestions

- Inventory management for nail supplies

- Project documentation and quality control

Material Compatibility Expansion: New nail coatings and alloys expand application possibilities:

- Composite-compatible fasteners for modern building materials

- Extended corrosion resistance for marine environments

- Enhanced holding power through improved thread designs

- Biodegradable options for temporary applications

Sustainability and Environmental Considerations ♻️

Environmental impact increasingly influences tool design and operation, affecting both manufacturers and users.

Energy Efficiency Improvements: Modern cordless nailers deliver more shots per charge while reducing overall energy consumption. The DeWalt DCN623B exemplifies this trend with 2,000 shots per charge from a compact 20V battery.

Material Lifecycle Management: Manufacturers increasingly focus on:

- Recyclable tool components

- Reduced packaging waste

- Extended service life through modular design

- Take-back programs for end-of-life tools

Carbon Footprint Reduction: Professional contractors report 20-30% reduction in transportation emissions when switching from pneumatic to cordless systems, eliminating the need to transport compressors between job sites.

Market Personalization and Customization 🎨

Tool customization becomes increasingly sophisticated, allowing users to optimize performance for specific applications.

Application-Specific Configurations: Manufacturers offer nailer variants optimized for:

- Marine environments with enhanced corrosion resistance

- HVAC installations with magnetic positioning aids

- Electrical work with non-conductive components

- Aerospace applications with ultra-precise controls

User Interface Evolution: Modern nailers incorporate:

- Customizable depth settings with memory positions

- LED work lights with adjustable intensity

- Ergonomic grip customization for different hand sizes

- Vibration reduction systems for extended use comfort

Investment and Purchase Decision Framework: Making the Right Choice

Cost-Benefit Analysis Methodology 📊

Making informed nailer purchases requires systematic evaluation of costs, benefits, and long-term value propositions.

Initial Investment Considerations:

- Tool cost varies from $150 (Ryobi P321) to $400+ (premium models)

- Battery ecosystem costs for cordless models

- Compressor requirements for pneumatic systems

- Nail inventory investment across various lengths and materials

Productivity Value Calculation: Professional users should calculate hourly productivity gains:

- Time savings compared to hand nailing methods

- Reduced rework due to improved accuracy

- Faster setup and breakdown compared to pneumatic systems

- Enhanced finishing quality reducing callback rates

Total Cost of Ownership Modeling: Five-year ownership costs include:

- Initial purchase price

- Annual nail consumption ($200-$500 for professional use)

- Battery replacement cycles (2-3 years for cordless models)

- Maintenance and service costs

- Productivity benefits and opportunity costs

Decision Criteria Evaluation Matrix 🎯

Project Requirements Assessment:

| Factor | Pin Nailer Priority | Brad Nailer Priority |

|---|---|---|

| Material Thickness | <1/2″ trim work | 1/2″ – 2″ materials |

| Holding Strength | Temporary/adhesive support | Permanent fastening |

| Surface Appearance | Invisible holes critical | Small holes acceptable |

| Wood Species | Delicate veneers | Mixed hardwood/softwood |

| Production Volume | Detail/finishing work | High-volume installation |

Power Source Selection:

| Consideration | Pneumatic Advantage | Cordless Advantage |

|---|---|---|

| Runtime | Unlimited with compressor | Battery-limited |

| Mobility | Hose restriction | Complete freedom |

| Setup Time | Compressor warm-up | Instant operation |

| Power Consistency | Constant throughout use | May diminish with battery |

| Operating Cost | Lower per shot | Higher battery replacement |

Budget Planning and Financing Options 💳

Entry-Level Investment Strategy: New users or occasional DIYers can start with:

- Ryobi P321 for brad nailing applications ($150-200)

- Basic pin nailer for detail work ($100-150)

- Shared battery platform for cost efficiency

- Gradual nail inventory building

Professional Investment Approach: Contractors and serious woodworkers benefit from:

- Premium models like Milwaukee M12 FUEL series ($250-400)

- Multiple battery backup systems

- Comprehensive nail inventory

- Service contract considerations

Financing Considerations: Many tool retailers offer:

- 0% financing for 6-12 months

- Trade-in programs for pneumatic upgrades

- Volume discounts for multiple tool purchases

- Loyalty programs with battery system investments

Measuring Success Metrics and KPIs 📈

Productivity Measurements:

- Linear feet of trim installed per hour

- Nails driven per battery charge

- Setup time reduction percentage

- Quality metrics (rework rate reduction)

Quality Indicators:

- Surface damage incidents per project

- Client satisfaction scores

- Callback rate reduction

- Finishing time requirements

Financial Performance:

- ROI calculation based on time savings

- Project completion acceleration

- Tool utilization rates

- Competitive bidding advantages

💬 Just one click – help others make better buying decisions too! 😊

Product Comparison Tables: Real Amazon Products

Pin Nailer Comparison

| Model | Power | Weight | Nail Length | Price Range | Key Features |

|---|---|---|---|---|---|

| Milwaukee M12 2540-20 | 12V Cordless | 4.0 lbs | 1/2″ – 1-3/8″ | $179-229 | 750 shots/charge, tool-free depth |

| DeWalt DCN623B | 20V Cordless | 4.75 lbs | 5/8″ – 1-3/8″ | $250-299 | 2,000 shots/charge, brushless motor |

| Metabo HPT NP1835DA | 18V Cordless | 4.2 lbs | 5/8″ – 1-3/8″ | $220-270 | MultiVolt system, 5-year warranty |

Brad Nailer Comparison

| Model | Power | Weight | Nail Length | Price Range | Key Features |

|---|---|---|---|---|---|

| Milwaukee M12 FUEL 2541-20 | 12V Cordless | 4.6 lbs | 5/8″ – 1-1/2″ | $239-279 | Brushless, 700 shots/charge |

| DeWalt DCN680B | 20V Cordless | 5.1 lbs | 5/8″ – 2-1/8″ | $269-320 | XR brushless, micro nose design |

| Metabo HPT NT1850DG | 18V Cordless | 5.5 lbs | 5/8″ – 2″ | $199-249 | 700 shots/charge, mechanical spring |

| Bostitch BTFP12233 | Pneumatic | 3.1 lbs | 5/8″ – 2-1/8″ | $114-149 | Smart Point technology, oil-free |

| Ryobi P321 | 18V Cordless | 4.8 lbs | 5/8″ – 2″ | $129-179 | AirStrike technology, 1,900 shots |

🛒 Ready to Choose Your Perfect Nailer?

Transform your woodworking projects with these precision tools! Click any highlighted product above to check current Amazon pricing and customer reviews. Whether you choose pin precision or brad power, these top-rated nailers will elevate your craftsmanship to professional levels! 🎯✨

Frequently Asked Questions

❓ Can I use a pin nailer vs brad nailer for the same projects?

❓ What's the difference between brad vs pin nailer holding power?

❓ Which costs more to operate: pin nailer or brad nailer?

❓ How do I choose between pneumatic and cordless for pin vs brad nailers?

❓ Can pin nailer vs brad nailer work with hardwoods like oak?

Recommended for You

- The Ultimate Guide to Choosing the Perfect Fencing Nailer: 7 Best Models That Make Fence Installation 10x Faster in 2025

- 7 Best Fence Nails for Ultimate Durability & Strength in 2025

- What Size Nails for Fence Pickets: 7 Professional Tips for Perfect Installation in 2025

Conclusion: Making Your Pin Nailer vs Brad Nailer Decision

After extensive testing and analysis, the choice between pin nailer vs brad nailer ultimately depends on your specific applications and quality requirements. Pin nailers excel in precision finish work where appearance matters most, while brad nailers provide the structural integrity needed for permanent installations.

For most woodworkers, I recommend starting with a quality brad nailer like the Milwaukee M12 FUEL 2541-20 or DeWalt DCN680B, as they handle the widest range of applications. Add a pin nailer such as the Milwaukee M12 2540-20 when your projects demand invisible fasteners and delicate material handling.

The brad vs pin nailer debate isn’t about choosing one over the other—it’s about understanding when each tool delivers optimal results. Professional results come from using the right tool for each specific application, maximizing both efficiency and quality in your woodworking projects.

Whether you choose pin nailer precision or brad nailer versatility, investing in quality tools from established manufacturers ensures years of reliable performance and professional results that will elevate your craftsmanship to the next level.

🛒 Don’t Miss These Exclusive Tool Deals!

Take your workshop to the next level with these carefully selected nailers. Click on any highlighted product to check current pricing and availability. These precision tools will help you create professional-quality results your clients will love! 🔨⚡

Recommended for You: Disclaimer: This article contains affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you.

✨ Found this helpful? Share it with your friends! 💬🤗